Shaft locking assemblies connects one or two components parts solidly to the drive shaft, which allows motion to be transmitted or to withstand an axial thrust. Friction connection enables gaps to be eliminated, thereby ensuring greater precision of the keyed components without requiring high precise tolerances. The thrust cones develop a pressure between the shaft and the hub by tightening clamping screws, which is capable of transmitting much higher torques than conventional keyway connection. The easy assembly and disassembly features give users many advantages, leading to further cost-saving. Suitable to connect any type of hub including flywheels, chain wheels, gears, levers, pulleys, eccentrics, couplings, etc.

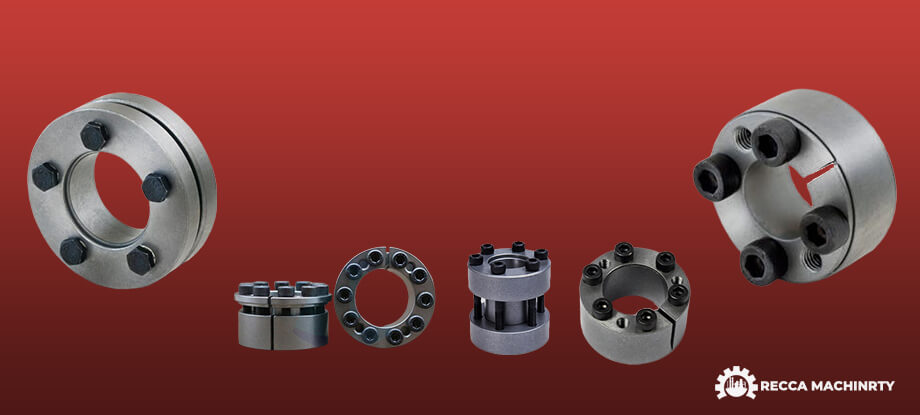

Recca Machinery provides its customers with different types of Shaft locking devices, which are designed to cover a broad range of applications.

Keyless Locking assemblies are also known as keyless shaft locking devices, cone clamping elements, power lock, shaft clamping elements, shrink discs, and keyless rigid couplings.

| Feature | RECCA SHAFT HUB LOCKING DEVICES TYPE | |||||||||||||||||

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | 14 | 15 | 16 | 17A | 17B | 18 | 19 | 20 | 22 | 33 | 34 | |

| Self-centering | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||

| Not self-centering | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||||

| Min. radial dimensions | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||||||

| Rapid maintenance and assembly | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Medium-to-low torque | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||||||

| Medium-to-high torque | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||

| High torque | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||||||

| Self-locking | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||

| Non self-locking | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||||

| Shaft install tolerance | H8 | H8 | H6/H8 | H8 | H8 | H8 | H8 | H8 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Hub install tolerance | H8 | H8 | H7/H8 | H8 | H8 | H8 | H8 | H8 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| NOTE:RECCA 03 recommended install dimension as per 1. Norminal Dimension H ≤ 38 mm : H6 For Shaft and H7 For Hub | ||||||||||||||||||

| Also name as: | RECCA | TOLLOK | BONFIX | Chiaravalli | BEA | SATI | SIT | COMPOMAC | MAV | ITALBLOCK | Poggi | KINLOK |

| LOCKING DEVICE | RECCA 01 | TLK200 | CCE2000 | RCK40 | BEA BK40 | KLGG | Type 1 | Conex A | 2005 | CN210 | CAL-A | LOK30 |

| CLAMPING DEVICE | RECCA 02 | TLK110 | CCE1000 | RCK80 | BEA BK80 | KLCC | Type 3 | Conex B | 5061 | CN55 | CAL-B | LOK10 |

| KEYLESS LOCKING DEVICES | RECCA 03 | TLK300 | CCE3000 | RCK50 | BEA BK50 | KLNN | Type 2 | Conex C | 3003 | CN31 | CAL-C | LOK80 |

| KEYLESS LCOKING ASSEMBLY | RECCA 04 | TLK130 | CCE4000 | RCK70 | BEA BK70 | KLDA | Type 5A | Conex D | 6901 | CN54/N | CAL-D | LOK20A |

| LOCKING ELEMENTS | RECCA 05 | TLK132 | CCE4100 | RCK13 | BEA BK13 | KLAA | Type 6 | Conex DS | 1062 | CAL-DS | ||

| SHAFT HUB CONNECTION | RECCA 06 | TLK131 | CCE4500 | RCK71 | BEA BK71 | KLDB | Type 5B | Conex E | 6902 | CN54/S | CAL-E | LOK20B |

| SHAFT LOCKING DEVICES | RECCA 07 | TLK133 | CCE4600 | RCK16 | BEA BK16 | KLAB | Conex ES | 1061 | CN9/4 | CAL-ES | ||

| POWER LOCK | RECCA 14 | TLK603 | CCE8000 | RCK19 | BEA BK19 | KLPP | Conex SD | 2008 | CAL-SD | |||

| CLAMPING POWER LOCK | RECCA 15 | TLK134 | CCE4900 | RCK15 | BEA BK15 | KLBB | Conex EP | 3061/2/3 | ||||

| SHRINK DISC | RECCA 16 | KLHH | CONEX L | CAL-L | ||||||||

| LOCKING ASSEMBLY | RECCA17A | BEA BK17 | KLFC | |||||||||

| LOCKING BUSHES | RECCA 17B | TLK250 | RCK55 | KLFF | Conex H | CAL-I | ||||||

| CONE CLAMPING ELEMENTS | RECCA 18 | RCK61 | BEA BK61 | KLSS | 7903 | |||||||

| Shaft Clamping Collar | RECCA 19 | TLK400 | CCE9500 | RC11 | BEA BK11 | KLEE | Type4 | 4061 | CN911 | CAL-F | ||

| CLAMPING POWER LOCK | RECCA 33 | |||||||||||

| SHAFT HUB LOCKING DEVICE | RECCA 34 |

| SHAFT LOCKING ASSEMBLIES ALSO NAME AS : | RECCA TYPE | KTR | RINGBLOK | BIKON | Ringfeder | RINGSPANN | TAS -Schafer | VBLOK | ECOLOC | PETER GERWAH |

| LOCKING DEVICE | RECCA 01 | KTR100/KTR101 | 1120 | 4000 | RFN7012 | RLK200 | TAS 3020 | VK400 | ||

| CLAMPING DEVICE | RECCA 02 | KTR250 | 1100 | 8000 | RFN7110 | RLK110 | VK800B 03 | 7110 | PSV2010.1 | |

| KEYLESS LOCKING DEVICES | RECCA 03 | KTR150 | 1060 | 5000 | RFN8006 | RLK300 | ||||

| KEYLESS LCOKING ASSEMBLY | RECCA 04 | KTR200 | 1300.1 | 1003/7000A | RFN7013.0 | RLK130 | VK700 | 7004 | PSV2007 | |

| LOCKING ELEMENTS | RECCA 05 | KTR203 | 1710 | 1003 | RFN7013.0 | RLK132 | TAS 3003 | VK160 | 7003 | PSV2006 |

| SHAFT HUB CONNECTION | RECCA 06 | KTR201 | 1300.2 | 1006/7000B | RFN7013.1 | RLK131 | VK700.1 | 7007 | PSV2007.3 | |

| SHAFT LOCKING DEVICES | RECCA 07 | KTR206 | 1720 | 1006 | RFN7013.1 | RLK133 | TAS 3006 | VK130 | 7006 | PSV2006.3 |

| POWER LOCK | RECCA 14 | KTR603 | 2200 | 1029.1 | RFN4071 | RLK603 | ||||

| CLAMPING POWER LOCK | RECCA 15 | KTR225 | RLK134 | |||||||

| SHRINK DISC | RECCA 16 | |||||||||

| LOCKING ASSEMBLY | RECCA17A | |||||||||

| LOCKING BUSHES | RECCA 17B | KTR125 | 1500 | 5500SP | RLK250 | |||||

| CONE CLAMPING ELEMENTS | RECCA 18 | KTR105 | 7002 | |||||||

| Shaft Clamping Collar | RECCA 19 | KTR400 | 1800 | 1012 | RFN7015 | RLK400 | TAS 3012 | VK112 | 7005 | PSV2061 |

| CLAMPING POWER LOCK | RECCA 33 | RFN7014 | PSV2005 | |||||||

| SHAFT HUB LOCKING DEVICE | RECCA 34 | 1015.0/1015.1 | 7009 | PSV2009 |

| SHAFT LOCKING ASSEMBLIES ALSO NAME AS : | RECCA TYPE | CHINA STANDARD | KANA | TSUBAKI | CHALLENGE | SKF | FENLOCK | B-LOC |

| LOCKING DEVICE | RECCA 01 | Z2 | KANA 200 | TSUBAKI AS | CHALLENGE 01 | SKF FX10 | FLK200 | B-LOC B400 |

| CLAMPING DEVICE | RECCA 02 | Z11 | TSUBAKI TF | CHALLENGE 02 | SKF FX20 | FLK110 | B-LOC B800 | |

| KEYLESS LOCKING DEVICES | RECCA 03 | Z11 | KANA 300 | TSUBAKI EL | CHALLENGE 03 | SKF FX30 | FLK300 | B-LOC B112 |

| KEYLESS LCOKING ASSEMBLY | RECCA 04 | Z3 | CHALLENGE 04 | SKF FX41 | FLK130 | |||

| LOCKING ELEMENTS | RECCA 05 | Z3B | KANA 201 | CHALLENGE 05 | SKF FX50 | FLK132 | ||

| SHAFT HUB CONNECTION | RECCA 06 | Z13 | CHALLENGE 06 | FLK131 | ||||

| SHAFT LOCKING DEVICES | RECCA 07 | Z8 | KANA 201 | CHALLENGE 07 | SKF FX51 | FLK133 | ||

| POWER LOCK | RECCA 14 | Z7B | TSUBAKI SL | CHALLENGE 14 | SKF FX190 | FLK603 | B-LOC SD10 | |

| CLAMPING POWER LOCK | RECCA 15 | Z6 | CHALLENGE 15 | SKF FX52 | FLK134 | |||

| SHRINK DISC | RECCA 16 | CHALLENGE 16 | SKF FX120 | |||||

| LOCKING ASSEMBLY | RECCA17A | SKF FX80 | ||||||

| LOCKING BUSHES | RECCA 17B | Z19B | CHALLENGE 21 | FLK250L | ||||

| CONE CLAMPING ELEMENTS | RECCA 18 | SKF FX350 | ||||||

| Shaft Clamping Collar | RECCA 19 | Z12A | TSUBAKI AD | CHALLENGE 19 | SKF FX60 | FLK400 | B-LOC B112 | |

| CLAMPING POWER LOCK | RECCA 33 | Z4 | ||||||

| SHAFT HUB LOCKING DEVICE | RECCA 34 |

◆Keyless connect shaft-hub with zero backlashes and largely self-centering

◆Increased shaft strength with high torque transmission

◆Simple installation and disassembly

◆Unaffected by alternating torques

◆Erases fretting corrosion

◆True running even at high speed

◆Long lifetime and easy maintenance

◆Carbon Steel with tempering and quenching

◆Premium roughness between Ra0.8 till 1.6 ㎛

◆Shaft Hub tolerance H8

◆DIN912-12.9 locking screws

◆Stainless steel available as per customer need

◆Plastic bag

◆Box

◆Carton

◆Wooden case with pallet