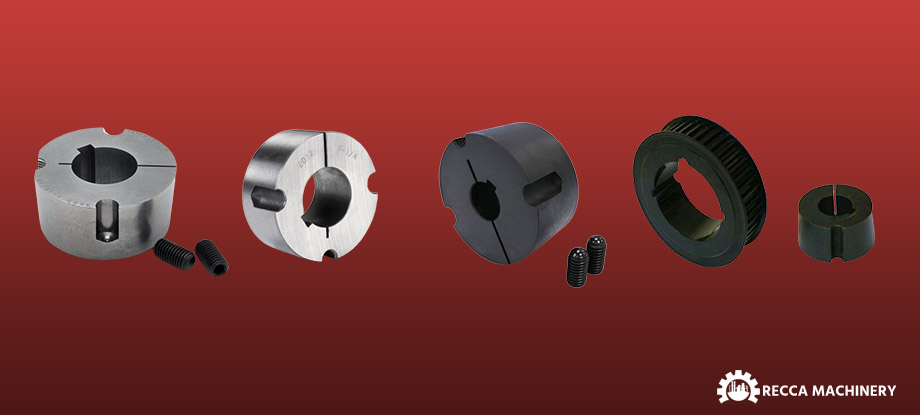

Taper lock bushing is one of the most convenient and economical way to secure a part to a mating shaft without the use of any special tools.A taper bushing quickly aligns or locks the pulley, sprocket or toothed coupling to the drive shaft.Taper bushes are already provided with the required bore, keyway, threaded holes and setting screws, thus allowing to save time and money on machining processes. The taper lock bush is reusable after replacement and Recca not only offers a variety of standard bushings, but also custom bore or keyway in metric or inch sizes to suit the customer’s specific needs. The bushings are available in steel or cast iron.

Recca Machinery is professional taper lock bushing manufacture and supplier in China. We’ve started taper lock bushes production since the year 2006 and always met the rising demand of its customers. The standard timing pulleys are supplied with a small prebore so that they can be machined according to customers’ demand. Besides, taper bore is available. All Recca taper bushing can be made of special materials, with heat and surface treatments according to customer specifications. We can supply both metric bore or inch bore size taper bushings.

Here following are all the different standard types of taper lock bushes can be supplied by us: 1610 1615 2012 2517 3020 3030 3525 3535 4030 4040 4545 5040 5050

We have a full series of standard bushes to meet the various demands of the power transmission and precision machinery markets. But we know that sometimes it takes something special to get the job done. Recca machinery supplies custom service can produce custom taper lock bushing according to your drawings to meet your unique performance and material specifications.

Recca Machinery has the engineering and design capabilities to manufacture custom taper lock bushes to meet your specific needs. Available in a variety of styles, sizes, and configurations. We can customize a taper bushing to fit your needs. Our laser engraving machines and package customization service can meet your specific typing and package needs.

| Bush type | Dimensions (mm) | Max. Torque | Screw tightening | Weight | ||||

| Bore (ISO E 8) | D1 | S | Type | (Nm) | Screws | torgue (Nm) | (kg) | |

| 1008 | 9 10 11 12 14 15 16 18 19 20 22 24* 25* | 35.0 | 22.3 | 1 | 136 | 1/4″ x 1/2″ | 5.6 | 0.16 |

| 1108 | 9 10 11 12 14 15 16 18 19 20 22 24 25 28* | 38.0 | 22.3 | 1 | 147 | 1/4″ x 1/2″ | 5.6 | 0.16 |

| 1210 | 11 12 14 15 16 18 19 20 22 24 25 28 30 32 | 47.5 | 25.4 | 1 | 407 | 3/8″ x 5/8″ | 19.6 | 0.32 |

| 1215 | 14 19 20 24 25 28 | 47.5 | 38.1 | 1 | 407 | 3/8″ x 5/8″ | 19.6 | 0.5 |

| 1610 | 14 15 16 18 19 20 22 24 25 28 30 32 35 38 40 42* | 57 | 25.4 | 1 | 486 | 3/8″ x 5/8″ | 19.6 | 0.41 |

| 1615 | 14 16 18 19 20 22 24 25 28 30 32 35 38 40 42* | 57 | 38.1 | 1 | 486 | 3/8″ x 5/8″ | 19.6 | 0.6 |

| 2012 | 14 16 18 19 20 22 24 25 28 30 32 35 38 40 42 45 48 50 | 70 | 31.8 | 1 | 808 | 7/16″ x 7/8″ | 30.4 | 0.75 |

| 2517 | 16 18 19 20 22 24 25 28 30 32 35 38 40 42 45 48 50 55 60 65* | 85.5 | 44.5 | 1 | 1310 | 1/2″ x 1″ | 48 | 1.06 |

| 3020 | 25 28 30 32 35 38 40 42 45 48 50 55 60 65 70 75 | 108 | 50.8 | 1 | 2710 | 5/8″ x 1″1/4 | 90 | 2.5 |

| 3030 | 35 38 40 42 45 48 50 55 60 65 70 75 | 108 | 76.2 | 1 | 2710 | 5/8″ x 1″1/4 | 90 | 3.75 |

| 3525 | 35 38 40 42 45 48 50 55 60 65 70 75 80 85 90 | 127 | 64.9 | 2 | 5060 | 1/2″ x 1″1/2 | 112 | 4.2 |

| 3535 | 35 38 40 42 45 48 50 55 60 65 70 75 80 85 90 | 127 | 88.9 | 2 | 5060 | 1/2” x 1”1/2 | 112 | 5.13 |

| 4030 | 40 42 45 48 50 55 60 65 70 75 80 85 90 100 | 146 | 76.2 | 2 | 8740 | 5/8” x 1”3/4 | 169 | 6.75 |

| 4040 | 40 42 45 48 50 55 60 65 70 75 80 85 90 95 100 | 146 | 101.6 | 2 | 8740 | 5/8” x 1”3/4 | 169 | 7.68 |

| 4545 | 55 60 65 70 75 80 85 90 95 100 | 162 | 115 | 2 | 12400 | 3/4” x 2” | 192 | 10.56 |

| 5040 | 55 60 65 70 75 80 85 90 95 100 | 177.6 | 101.6 | 2 | 14200 | 7/8” x 2”1/4 | 271 | 14.2 |

| 5050 | 70 75 80 85 90 95 100 105 110 115 120 125 | 177.6 | 127 | 2 | 14200 | 7/8” x 2”1/4 | 271 | 15.17 |

| Material: Cast Iron / Steel | Ordering sample bore in mm Ф12: TB 1008-12 | |||||||

◆ Material: cast iron, steel or stainless steel which is available upon to customer special requirement

◆ Surface treatment: Black-phosphated or original color without finishing

◆ Easy installation and Easy disassembly

◆ Machined to high precise tolerance

◆ Available in a variety of metric and imperial sizes

◆ OEM/ODM available

◆ Plastic bags/kraft paper+cartons for light weight

◆ Wooden case for heavy weight

◆ According to the customer demand

Taper bushings are used in Construction Industry, Fluid Industry, Automotive Industry, Municipal Industry and so on field.