Plastic Timing belt pulleys are a wheel on a shaft or an axle. It is developed in order to support the change of direction and movement of a belt or a cable along the circumference. Pulley is grooved in between two flanges all over its circumference. Toothed belts and pulleys are of major importance in synchronous drives based on flexible components.Their curvilinear tooth profile was designed with high-speed and provide excellent registration without a loss in torque carrying capability making them ideal for precise registration applications and heavy loads. Timing belt drives are increasingly replacing inefficientroller chain sprockets for the transfer of power from shaft to shaft, torque multiplication, speed reduction, speed increase, and shaft synchronization.

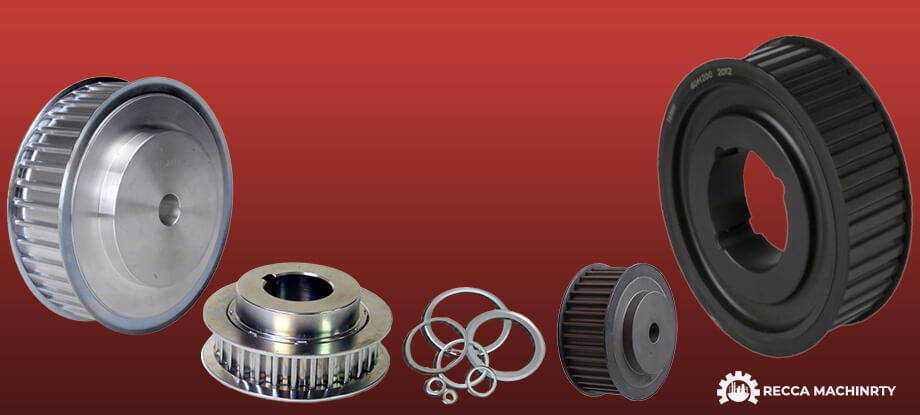

Recca Machinery is professional timing belt pulleys manufacture and supplier in China. We’ve started timing pulleys production since the year 2006 and always met the rising demand of its customers. The standard sychronous pulleys are supplied with a small prebore so that they can be machined according to customers’ demand. Besides, taper bore is available. All Recca Timing Pulleys can be made of special materials, with heat and surface treatments according to customer specifications. Here following are all the different types of timing belt pulleys can be supplied by us:

| TEETH PROFILE | PITCH |

|---|---|

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | 0.08″(2.032MM) |

| XL | 1/5″(5.08MM) |

| L | 3/8″(9.525MM) |

| H | 1/2″(12.7MM) |

| XH | 7/8″(22.225MM) |

| XXH | 1 1/4″(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

◆ AlCuMgPb 6061 6082 Aluminum Timing Pulley

◆ C45E 1045 S45C Carbon Steel Timing Pulley

◆ GG25 HT250 Cast Iron Timing Pulley

◆ SUS303 SUS304 AISI431 Stainless Steel Timing Pulley

◆ Other material as per customer demand: cooper, bronze and plastic

◆ Anodized surface -Aluminum Pulleys

◆ Hard anodized surface — Aluminum Pulleys

◆ Black Oxidized surface — Steel Pulleys

◆ Zinc plated surface — Steel Pulleys

◆ Phosphating surface — Steel Pulleys; Cast Iron Pulleys

◆ Nickel plated surface –Steel Pulleys; Cast Iron Pulleys

Machining tolerance can meet H6 precision or customized.

Advantage: OEM/ODM services provide

◆ Plastic bags/kraft paper+cartons for light weight; Wooden case for heavy weight

◆ According to the customers ‘ demand

Toothed pulleys are coded on the basis of:

– the number of teeth

– pitch, expressed by one or more letters

– width, expressed in hundredths of an inch

– flange ( if any ) expressed by the letter F.

Exemple:

Pulley 10 XL 037 has:

– 10 teeth

– pitch identified by letters XL

– a belt width of 37 mm

Pulley Drawings Symbols

N = Number of pitch lengths or teeth on a pulley

P = Pitch is the distance between the axes of two adjacent teeth irrespective of whether these teeth are on the pulley or

the belt provided that measurement is taken on the circumferenceor pitch line

t = Belt thickness

Dp = The diameter of the pulley pitch is obtained from formula Dp = (P · N)/P

De = External diameter of pulley De=Dp – NF

Df = Flange diameter

d = Bore diameter

Dm = Hub diameter

F = Tooth width

L = Total length incl. Hub

This treatment is carried out on steel pulleys mostly for appearance. The resulting black iron oxide coating will not chip, peel, flake or rub off. A chemical degreasing pretreatment (pickling) is made before black oxiding and causes the deoxidation of the

pulleys. After black finishing, pulleys are oiled in order to protect surface from atmospheric oxidation. This treatment therefore will merely produce a black finish coating but it is not a corrosion-resistant treatment. To achieve a level of corrosion resistance, oil is applied on the pulleys.

This treatment is made on cast iron pulleys in order to obtain a good antioxidizing protection,

without modifying dimensionally the profiles and forms of the treated parts.The phosphating process, that produces on the surfaces of pieces a thin microcrystalline deposit with a basis of manganese and iron phosphates, is completed by an impregnation in protective oils that improves the resistance to the oxidizing agents of the microcrystalline coat itself. In addition to this, the phosphating gives, to the treated parts, a pleasant aeshetic appearance, due to the blackgray colour produced on their surface.