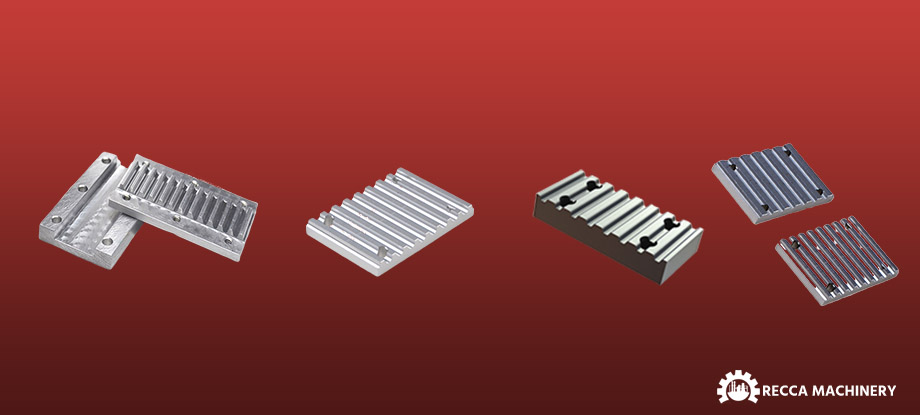

Timing belt clamp plates are a safe and yet cost-effective fixing elements for flat belts and drive belts in finite design (sold by length). The clamp plates are generally used to fix the belt ends and are deployed in a great many applications within drive technology such as lift and linear applications. Tooth plates can also be used to set the pre-tension force.

Recca Machinery is a professional gear and timing clamp plate manufacture and supplier in China. We’ve started toothed clamp plates production since the year 2006 and always met the rising demand of its customers. Clamp fixed tooth plate is suitable for a safe and cost-effective connection on both ends of the openings of the timing belt( Synchronous belt) or drive belt, and with the machine fixed to achieve transmission. Recca machinery supplies not only aluminum arc clamp tooth plate with T/AT/HTD/3M/5M/8M/POLYCHAIN® GT popular tooth profile for open synchronous belt( Timing belt) connection but also accept other customized tooth profile order according to customer need. We can supply special surface treatment such as chemical nickel plating as well.

| Available Special Request | Different Material : Steel, Stainless Steel |

| Special Length can be customized | |

| Anti-corrosive surface treatments for speical needs |

| Part No. | Pitch | L | B | Ø d | F | C | S | H | Weight Kg. |

|---|---|---|---|---|---|---|---|---|---|

| XL 037 | 5.08 | 42.5 | 28.5 | 5.5 | 6 | 3.5 | 8 | 9.5 | 0.02 |

| L 050 | 10 | 76.6 | 39 | 9 | 8 | 5 | 15 | 12.7 | 0.1 |

| L 075 | 9.53 | 76.6 | 45 | 9 | 8 | 5 | 15 | 19.1 | 0.12 |

| L 100 | 9.53 | 76.6 | 51.5 | 9 | 8 | 5 | 15 | 25.4 | 0.14 |

| H 050 | 12.7 | 106.9 | 45 | 11 | 10 | 9 | 22 | 12.7 | 0.25 |

| H 075 | 12.7 | 106.9 | 51 | 11 | 10 | 9 | 22 | 19.1 | 0.28 |

| H 100 | 12.7 | 106.9 | 57.5 | 11 | 10 | 9 | 22 | 25.4 | 0.32 |

| 5M 9 | 5 | 41.5 | 28 | 5.5 | 6 | 3.2 | 8 | 9 | 0.02 |

| 5M 15 | 5 | 41.5 | 34 | 5.5 | 6 | 3.2 | 8 | 15 | 0.03 |

| 5M 25 | 5 | 41.5 | 44 | 5.5 | 6 | 3.2 | 8 | 25 | 0.04 |

| 8M 20 | 8 | 66 | 45 | 9 | 8 | 5 | 15 | 20 | 0.1 |

| 8M 30 | 8 | 66 | 55 | 9 | 8 | 5 | 15 | 30 | 0.12 |

| 8M 50 | 8 | 66 | 75 | 9 | 8 | 5 | 15 | 50 | 0.17 |

| 8M 85 | 8 | 66 | 110 | 9 | 8 | 5 | 15 | 85 | 0.25 |

| 14M 40 | 14 | 116 | 71 | 11 | 10 | 9 | 22 | 40 | 0.4 |

| 14M 55 | 14 | 116 | 86 | 11 | 10 | 9 | 22 | 55 | 0.5 |

| 14M 85 | 14 | 116 | 116 | 11 | 10 | 9 | 22 | 85 | 0.68 |

| 14M 115 | 14 | 116 | 146 | 11 | 10 | 9 | 22 | 115 | 0.85 |

| 14M 170 | 14 | 116 | 201 | 11 | 10 | 9 | 22 | 170 | 1.14 |

| T 5 10 | 5 | 41.8 | 29 | 5.5 | 6 | 3.4 | 8 | 10 | 0.02 |

| T 5 16 | 5 | 41.8 | 35 | 5.5 | 6 | 3.4 | 8 | 16 | 0.03 |

| T 5 25 | 5 | 41.8 | 44 | 5.5 | 6 | 3.4 | 8 | 25 | 0.04 |

| T10 16 | 10 | 80 | 41 | 9 | 8 | 5 | 15 | 16 | 0.11 |

| T10 25 | 10 | 80 | 50 | 9 | 8 | 5 | 15 | 25 | 0.14 |

| T10 32 | 10 | 80 | 57 | 9 | 8 | 5 | 15 | 32 | 0.16 |

| T10 50 | 10 | 80 | 75 | 9 | 8 | 5 | 15 | 50 | 0.22 |

| AT5 10 | 5 | 41.8 | 29 | 5.5 | 6 | 3.4 | 8 | 10 | 0.02 |

| AT5 16 | 5 | 41.8 | 35 | 5.5 | 6 | 3.4 | 8 | 16 | 0.03 |

| AT5 25 | 5 | 41.8 | 44 | 5.5 | 6 | 3.4 | 8 | 25 | 0.04 |

| AT10 16 | 10 | 80 | 41 | 9 | 8 | 5 | 15 | 16 | 0.11 |

| AT10 25 | 10 | 80 | 50 | 9 | 8 | 5 | 15 | 25 | 0.14 |

| AT10 32 | 10 | 80 | 57 | 9 | 8 | 5 | 15 | 32 | 0.16 |

◆ Aluminum

◆ Carbon Steel

◆ Stainless Steel

◆ Anodized surface — Aluminum plates

◆ Hard anodized surface — Aluminum plates

◆ Nickel plated surface — Steel plates

Teeth Quantity: 10-110 teeth or customized

Inner Bore :2-200mm H7 precision or customized

Advantage: OEM/ODM services provide

◆ Plastic bags/kraft paper+cartons for light weight; Wooden case for heavy weight

◆ According to the customers ‘ demand