What types of pulleys are available for modern industrial use?

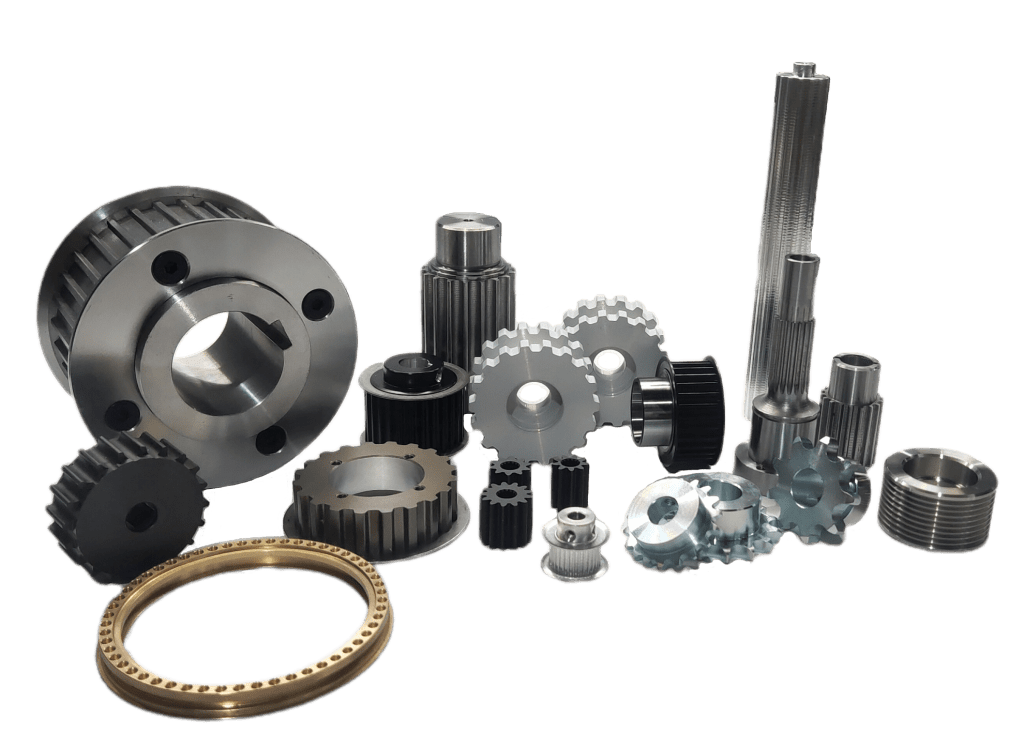

For modern industrial use, pulleys are generally defined by belt type. The pulleys are sprocket,synchronous, flat, round and V belts, which are used for the corresponding belt type. For example, synchronous belt pulleys contain teeth with notches that are spaced to engage the teeth of the matching belt. For flat belt pulleys, on the other hand, do not contain teeth because they are used for flat, smooth belts.V-belt pulleys contain an inclined belt track to fit the passing V-belt.

- Chain&Sprocket – Sprockets

- Flat Belt – Flat belt pulley

- Timing Belt – Timing belt pulley

- V-Belt- V Belt pulley

There are three structures of a pulley system in industry using:

- One has a fixed axle

- One has a moveable axle

- A compound, which is a mixture of the two

What are timing belt pulleys

Timing belt pulleys are a wheel on a shaft or an axle. It is developed in order to support the change of direction and movement of a belt or a cable along the circumference. Pulley is grooved in between two flanges all over its circumference. Toothed belts and pulleys are of major importance in synchronous drives based on flexible components.Their curilinear tooth profile was designed with high-speed and provide excellent registration without a loss in torque carrying capability making them ideal for precise registration applications and heavy loads. Timing belt drives are increasingly replacing inefficientroller chain sprockets for the transfer of power from shaft to shaft, torque multiplication, speed reduction, speed increase, and shaft synchronization.

Adavantages of timing belt pulley

Timing belts maintain system timing better through the use of a toothed profile and toothed pulleys or sprockets, and typically have a higher power density, allowing for smaller belt and pulley packages for a similar load. Because of these improvements, timing belts are also usually a more expensive option, are also usually a more expensive option.

- high level of synchronicity

- Low noisy

- No lubrication need

- A higher power density

- smaller belt and package for a similar load

Applications of Timing belt pulleys

Pulleys are widely used in marine, shipping and nautical applications; they also find use in various pieces of industrial equipment and machinery. For timing belt pulleys, they are used in industries where need an extremely high level of synchronicity. And the pulley must be able to perform under high rotational speeds of thousands of RPMs which can easily be seen during a typical driving profile. The toothed part of the belts stay effective in producing greater power transmissions and this property is found to be very suitable in driving automobile motors. Toothed belt supports for increasing the engine power and reduces the engine noise. Here, we list some typical timing belt pulley applications in industries.

Timing belt pulley applications

●Projection equipment

●Display equipment

●Printing machinery

●Laundry machinery

●Paper machinery

●Washers

●Brick and Clay pug mills

●Sawmill machinery

●Mills, oven, and paper pulpers

●Agitators for liquid

Available materials for timing belt pulley

Pulleys can be made from a variety of materials, including various plastics, woods, and metals. Industrial pulleys are typically made of steel and aluminium alloys, but modern industry has a wide variety of metals to meet different operating environments and performance requirements. Here are some common materials used to make synchronizer pulleys

- AlCuMgPb 6061 6082 Aluminum Timing Pulley

- C45E 1045 S45C Carbon Steel Timing Pulley

- GG25 HT250 Cast Iron Timing Pulley

- SUS303 SUS304 AISI431 Stainless Steel Timing Pulley

- Other material as per customer demand: cooper, bronze and plastic

Available surface treatment for timing pulley

- Anodized surface -Aluminum Pulleys

- Hard anodized surface — Aluminum Pulleys

- Black Oxidized surface — Steel Pulleys

- Zinc plated surface — Steel Pulleys

- Phosphating surface — Steel Pulleys; Cast Iron Pulleys

- Nickel plated surface –Steel Pulleys; Cast Iron Pulleys